ISO/IEC 17025:2017 is now a recognised symbol for quality in laboratory management, and assures technical expertise and global acceptance of ISO/IEC 17025 accredited laboratories’ test reports for the purposes of free trade and regulatory acceptance.

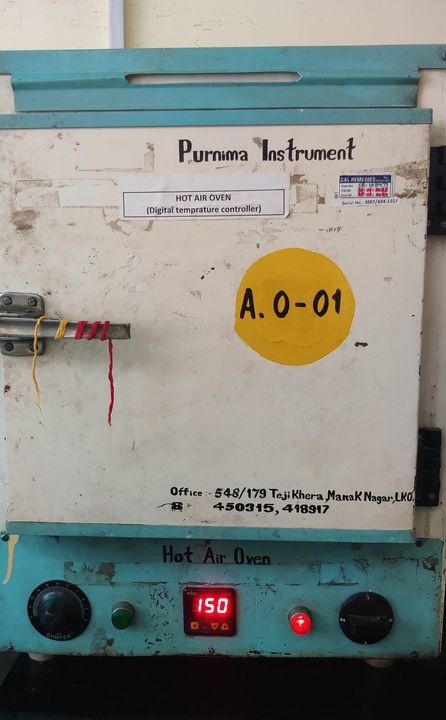

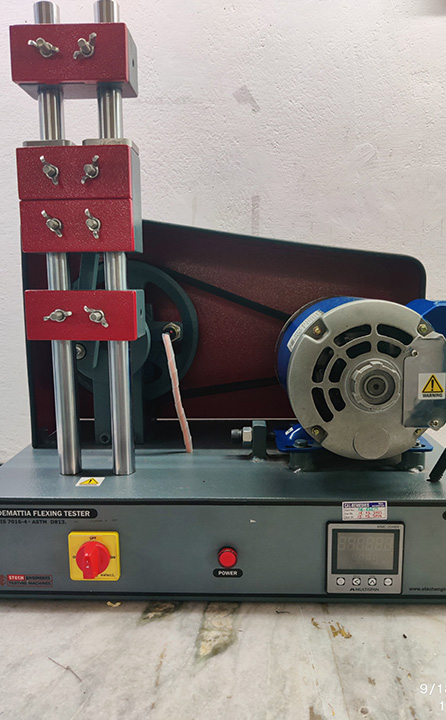

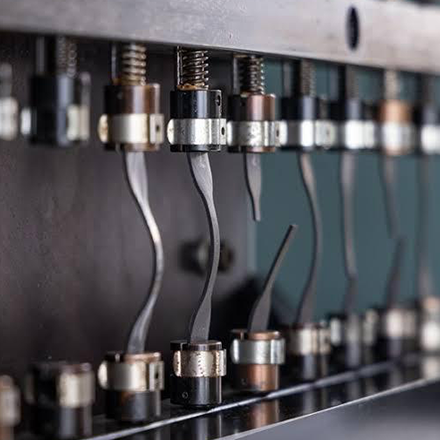

We have our own robust rubber testing facility that includes following machines for testing :

RSI’s NABL Rubber Testing Laboratory is a state-of-the-art facility dedicated to ensuring the quality and reliability of rubber products. Equipped with cutting-edge technology and staffed by highly trained experts, this laboratory plays a crucial role in assessing various critical characteristics such as tensile strength, elasticity, chemical composition, and resistance to environmental factors. Industries spanning aeronautical , railways , automotive, construction, healthcare, and more rely on rubber testing to guarantee safety, durability, and compliance with stringent standards. This meticulous scrutiny enhances consumer confidence, fosters product reliability, and supports innovation in rubber-based applications. Rubber testing is the cornerstone of quality assurance, underpinning diverse sectors and their commitment to excellence.

RSI’s commitment to adhering to stringent quality standards makes it a trusted source for businesses seeking to maintain the highest quality standards for their rubber products.

S.No |

Discipline / Group |

Materials or Products tested |

Component, parameter or characteristic tested / Specific Test Performed / Tests or type of tests performed |

Test Method Specification against which tests are performed and / or the techniques / equipment used |

|---|---|---|---|---|

Permanent Facility |

||||

1 |

CHEMICAL- RUBBER & RUBBER PRODUCTS |

Rubber vulcanizates |

Ash Content |

ASTM D 297 |

2 |

CHEMICAL- RUBBER & RUBBER PRODUCTS |

Rubber vulcanizates |

Identification of Polymer |

IS 3400 (Part-22) |

3 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

% Change in Elongation at Break after Heat Ageing |

ASTM D573 |

4 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

% Change in Elongation at Break after Liquid Ageing |

ASTM D 471 |

5 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

% Change in Tensile Strength after Heat Ageing |

ASTM D 573 |

6 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

% Change in Tensile Strength after Heat Ageing |

IS 3400 (Part-4) |

7 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

% Change in Tensile Strength after Liquid Ageing |

ASTM D 471 |

8 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

% Change in Volume after Liquid Ageing |

ASTM D 471 |

9 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

% Change in Volume after Liquid Ageing. |

ISO 1817 |

10 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

% Change in Weight after Liquid Ageing |

ASTM D 471 |

11 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

Brittleness Temperature |

ASTM D 2137 |

12 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

Change in Hardness after Heat Ageing |

ASTM D 573 |

13 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

Change in Hardness after Liquid Ageing |

ASTM D471 |

14 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

Compression Set |

ASTM D395, Method B |

15 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

Compression Set |

IS 3400 (Part-10, Section-1) |

16 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

Compression Set |

ISO 815-1 |

17 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

Density |

ASTM D297 |

18 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

Elongation after Rupture |

ASTM D 412 |

19 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

Elongation at Break ( %) |

ASTM D412 |

20 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

Elongation at Break (%) |

IS 3400 (Part-1) |

21 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

Flex Cracking Test |

ASTM D 813 |

22 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

Frost Resistance Coefficient |

GOST 13808 |

23 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

Hardness Shore A |

ASTM D 2240 |

24 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

Ozone Resistance Test |

ASTM D 1149 |

25 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

Tear Strength |

ASTM D 624 |

26 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

Tear Strength |

IS 3400 (Part-17) |

27 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

Tensile Strength |

ASTM D 412 |

28 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

Tensile Strength |

IS 3400 (Part-1) |

29 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

Tension Set |

IS 3400 (Part-13) |

30 |

MECHANICAL- RUBBER AND RUBBER PRODUCTS |

Rubber Vulcanizates |

Volumetric Swelling |

ISO 1817 |

RSI Metal Testing Laboratory stands as a beacon of excellence in the realm of materials evaluation. This state-of-the-art facility, accredited by the National Accreditation Board for Testing and Calibration Laboratories (NABL), is dedicated to ensuring the quality, integrity, and safety of metal-based products across industries. Equipped with cutting-edge technology and staffed by highly skilled metallurgists and technicians, it conducts a wide range of tests, from assessing the mechanical properties of metals to analyzing their chemical composition and corrosion resistance. RSI plays a pivotal role in facilitating innovation, enhancing product reliability, and assuring compliance with rigorous industry standards, thereby bolstering trust in the integrity of metal materials used in various applications.

S.No |

Discipline / Group |

Materials or Products tested |

Component, parameter or characteristic tested / Specific Test Performed / Tests or type of tests performed |

Test Method Specification against which tests are performed and / or the techniques / equipment used |

|---|---|---|---|---|

Permanent Facility |

||||

1 |

MECHANICAL- MECHANICAL PROPERTIES OF METALS |

Steel & Alloys |

Rockwell Hardness Test (HRC) |

ASTM E 18 |

All the indigenized components are regularly being supplied to our following customers

Lucknow | Kanpur | Koraput | Korwa | Nasik | Hyderabad | Banglore

1 BRD, 4 BRD, 29 ED, Air Force Chakeri, Kanpur

11 BRD, Air Force, Nasik

25ED, Devlali

3 BRD, Air Force, Chandigarh

5 BRD, Air Force, Coimbatore

Research Centre Imarat (DRDO),

Hyderabd